What Are Slab Spacers? Types, Uses & Why They Matter in Concrete Construction

What Are Slab Spacers? A Complete Guide for Concrete Construction

In modern concrete construction, slab spacers play a critical role in ensuring the durability, safety, and precision of reinforced structures. Whether you’re working on a residential floor slab, a precast element, or a highway bridge, using the correct spacer ensures that your reinforcing steel (rebar) stays in place—achieving the required concrete cover and structural integrity.

Let’s explore what slab spacers are, the various types available, and how to choose the right one for your project.

What Is a Slab Spacer?

A slab spacer is a small component—usually made of plastic or concrete—designed to support rebar (reinforcing bars) in the correct position before and during a concrete pour. It keeps the steel mesh or bars elevated at a consistent height to meet specified concrete cover requirements (commonly dictated by codes like Eurocode 2).

These spacers become a permanent part of the structure, ensuring the rebar remains embedded at the right depth for long-term durability and load resistance.

Why Is Proper Concrete Cover Important?

Concrete cover is the distance between the surface of embedded reinforcement and the outer surface of the concrete. Maintaining accurate cover:

- Prevents corrosion of steel bars

- Enhances load-bearing performance

- Improves fire resistance

- Complies with structural codes and inspections

Incorrect cover—too much or too little—can compromise the stability and lifespan of the structure.

Common Types of Slab Spacers

Different construction scenarios call for different types of spacers. Here are some of the most common slab spacer types found in the industry:

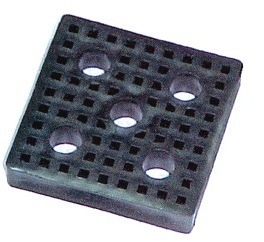

1. Plastic Slab Spacers

- Made from durable polypropylene (PP)

- Lightweight and non-corrosive

- Available in various sizes like 20MM, 25MM, 30MM

- Often used for mesh reinforcement in slab-on-grade or precast applications

- Ideal for horizontal use, not suitable for high-load vertical elements

2. Concrete Block Spacers

- Typically used in heavy-duty or load-bearing elements

- Made from high-strength fiber-reinforced concrete

- Offer excellent compressive strength and dimensional stability

- Suitable for use in impermeable concrete and harsh environments

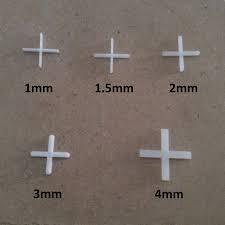

3. Stone Slab Joint Spacers

- Used in paving and landscaping

- Maintain uniform joint spacing between decorative stone or concrete tiles

- Allow for drainage and prevent edge damage

Key Features to Look For

When selecting a spacer, consider the following:

| Feature | Why It Matters |

|---|---|

| Height (e.g., 20MM) | Determines the level of cover for your rebar |

| Bar Size Compatibility | Must match your steel reinforcement (e.g., 6–10MM) |

| Material | Plastic for general use, concrete for heavy-duty |

| Locking Mechanism | Prevents dislodging during concrete pour |

| Packaging | Standard units come in 800–1000 PCS per bag |

| Durability | Weather-, chemical-, and pressure-resistant |

Applications of Slab Spacers

Slab spacers are widely used across a range of concrete projects:

- Floor Slabs & Suspended Slabs

- Precast Panels & Beams

- Retaining Walls

- Bridges, Tunnels, and Infrastructure

- Driveways and Pavements

- Shotcrete Applications

In precast factories, slab spacers are critical in ensuring repeatability, dimensional accuracy, and production efficiency.

Choosing the Right Spacer for Your Project

When selecting a slab spacer, keep these tips in mind:

- Match the spacer height to your design cover requirements

- Use plastic spacers for ease of installation in light-duty areas

- Opt for concrete spacers in areas with high load or high heat

- Ensure they’re tested for strength and weather resistance

Browse Our Slab Spacers

Conclusion

Slab spacers are more than just accessories—they’re essential for maintaining the structural quality and compliance of your concrete work. Whether you’re building a high-rise tower or a backyard patio, investing in the right spacers ensures your steel stays where it should—and your concrete performs at its best.